By John Gargasz

One of the highlights of GroceryShop 2021 in Las Vegas was Jon Fortt from CNBC interviewing Tony Xu CEO of DoorDash. Jon also hosts the weekly CNBC segment ‘On the other hand,’ where he argues both sides of the same issue, so this blog will take the same approach in reviewing the rapidly changing Convenience or ‘Q’ market and how automation may apply.

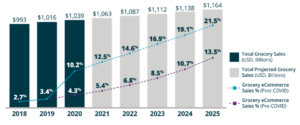

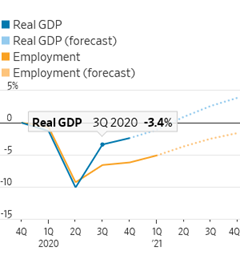

Let’s begin by looking at the last-mile delivery market for food and grocery – it earned revenue of approximately $25 billion and is expected to cross $72 billion in 2025, driven by the COVID-19 pandemic and new customer shopping behaviors. Online food retailers and convenience delivery companies that offer speed and variety are experiencing tremendous growth.

The likes of GoPuff, Getir, DoorDash, and others are among the current favorites of the venture capital market with tremendous funding and lofty goals for scale. Many of these players are transitioning from pure delivery companies to actual retailers with physical locations offering convenience SKU assortments ranging from roughly 1,000 to 5,000 items. For example, GoPuff recently acquired BevMo for $350 million in exchange for coast-to-coast business expansion and 161 store locations useful for acquiring new customers and supporting their local, manual micro fulfillment efforts.

The reality is that these convenience players are scrambling for user adoption, often underwriting orders and deliveries with promotions. There will be many failed ventures along the roadside as the economics of buying customers eventually drains the VC accounts. But there will also likely be a couple of big winners at the end of the day as well. DoorDash in particular is on a tear. They recently introduced DoubleDash — a new innovation that lets their existing 20 million restaurant customers add items from nearby stores to the original order for that last mile delivery.

Regardless of who emerges, the economics of replenishment and order fulfillment for these convenience operators must improve. They are opening small footprint (about 4,000 square feet) dark stores that are largely replenished and fulfilled manually by 4-5 people per location. There are even stories of employees going to other retailers and buying goods to stock their stores. Ouch!

So how can automation help this sector?

Alert Innovation, a leader in e-grocery fulfillment automation, regularly gets requests to provide its automation capabilities to convenience locations, but robotic automation costs money and if only five employees are fulfilling small basket sizes, with limited assortment at primarily peak hours of the day in small, manual micro fulfillment centers (MFC), it’s hard to make the numbers work.

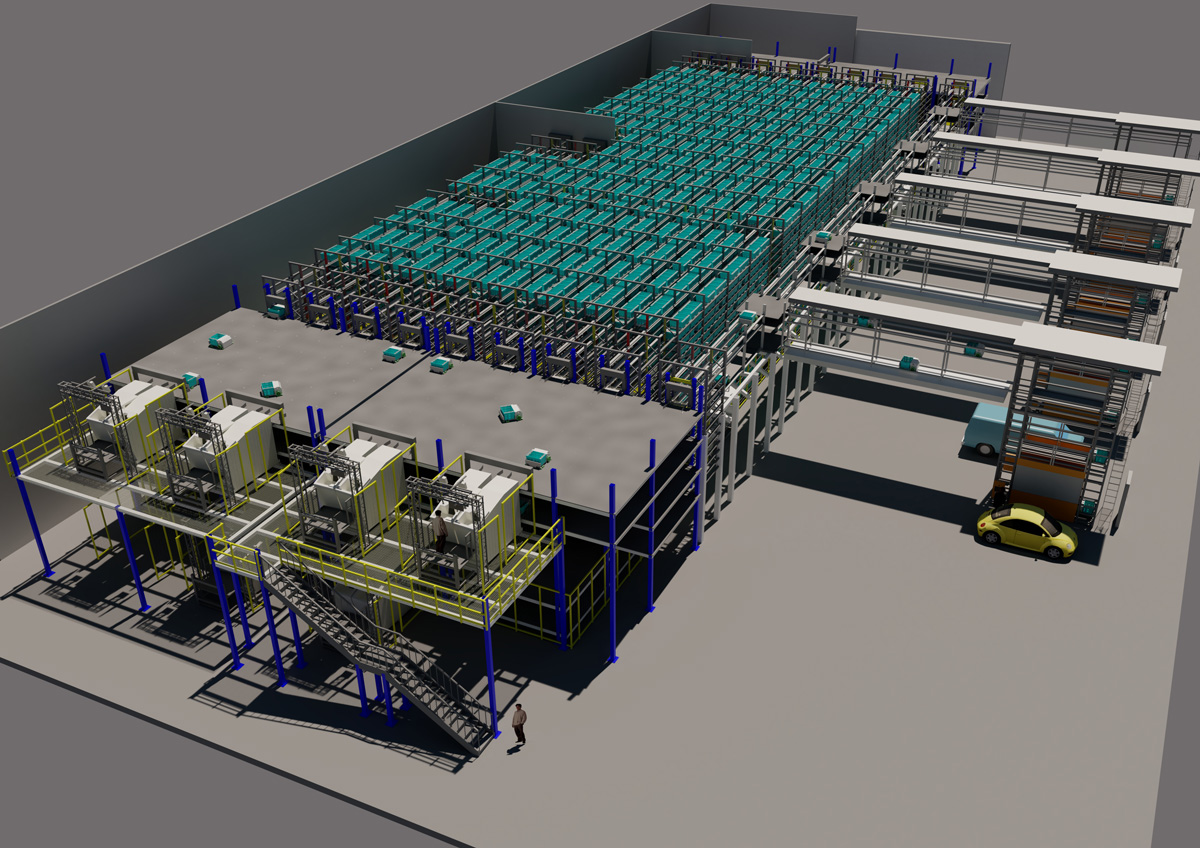

That said, there is absolutely a place for automation in convenience. The replenishment of multiple convenience outlets from a mid-sized micro fulfillment center within a 30–45-minute radius of the convenience locations is certainly viable and eliminates the replenishment chaos of these small sites.

A mid-sized automated MFC using the Alphabot system by Alert Innovation makes manual fulfillment at the local convenience location much more efficient with intelligent, less than case replenishment eliminating the need for full automation at each small convenience site.

And the Alphabot system offers new technologies that reduce the transport cost and carbon footprint from the automated MFC to the convenience location all the way through to the last mile delivery. So, yes, automation makes sense for the convenience market but not exactly in the manner those companies may be envisioning.

But now let’s look at convenience from the grocer’s perspective.

Convenience and grocery shopping typically serve two different shopping trips. One trip is to get groceries for stock up and fill in. The other trip is driven by impulse and cravings such as candy, beer, or a sandwich at 11pm. Convenience, by definition, demands a premium. Major cities have been the epicenter of this convenience trip market, proving that shoppers will spend billions for door-to-door deliveries.

As grocery retailers adopt automation technology at the store-level to better-serve their loyal shoppers, they are also installing a capability that makes them a quick-ship convenience outlet at minimal incremental cost, opening a tremendous opportunity for scaling their business with new “convenience” trip shoppers while improving their operational profits on their traditional trip shoppers.

E-grocery automated fulfillment systems like the Alphabot system operate 24×7 with minimal labor. That is their core value proposition. And these systems have peak demand and off-peak demand. For example, shoppers typically are collecting their large orders in the morning, afternoon/early evening during the week, and on weekend mornings. This creates an interesting opportunity for repurposing the automation system to fill convenience orders late at night and early in the morning, which are ‘off peak’ hours for the automation system when the grocers have excess automation capacity to fulfill the convenience demand with very little incremental cost.

And replenishment from distribution centers is already an area where grocery excels, especially when direct store delivery items are incorporated. These set-ups are often called Hub + Spoke models and allow retailers to use their existing inventory to satisfy a great radius of customers.

So there you have it – one huge opportunity for growth from two different perspectives.

(source: “Global Last-mile Food and Grocery Delivery Growth Opportunities” Report by Research & Markets: Wikipedia – DoorDash)

Alert developed the Alert Innovation Academy to train existing retail employees to work with the Alphabot system. Alert Innovation Academy has a career development trajectory that graduates workers from operators to robotics tech 1, tech 2 and even systems operation manager. Associates can start stocking shelves and become a robotics expert!

Alert developed the Alert Innovation Academy to train existing retail employees to work with the Alphabot system. Alert Innovation Academy has a career development trajectory that graduates workers from operators to robotics tech 1, tech 2 and even systems operation manager. Associates can start stocking shelves and become a robotics expert!