The COVID-19 pandemic has been a trying time for everyone and we can all agree a lesson learned is that humans crave in-person social interaction. We have also found a desire to get back to basics – games with the family, getting back to nature, walking the dog. Things that are fundamental needs from our 3 billion+ year evolution.

At first glance, you may say that automation, robots, and AI are further distancing humans from each other and our basic needs, but the data tell a different story.

Jobs and e-Grocery

In 2021, Amazon added 500,000 jobs, Walmart added 170,000 personal shoppers to their workforce and Instacart added 350,000 shoppers.

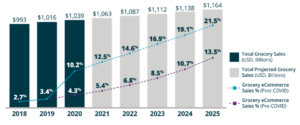

Job growth from ecommerce, specifically online grocery ordering and delivery, has been extraordinary by any measure. Experts can debate the sustainability of post-COVID online grocery demand (see Fig. 1), but the trend line has been set, and it is here to stay. According to a Brick Meets Click study, 69.3 million U.S. households placed one or more online orders in March 2021 alone.

Automating grocery fulfillment increases grocery store revenue and margins, improves order accuracy and increases speed of delivery. The improved profits are a result of maximizing the efficiency and productivity of the existing workforce using automation. This increased employee efficiency creates a slower rate of increase in jobs over time but that rate still continues to increase as the sector expands. Prior to barcode scanners, for instance, warehouse and retail employees spent hours and days counting inventory by hand with a great margin of error. Industry automation and revolutionary technology made the process more efficient and accurate, and enabled employees to spend more time engaging shoppers.

As online grocery continues to expand, the total number of workers needed will continue to rise. It’s true that other sectors may experience job losses, but grocers will generate more same store revenue, and let’s not forget that human to human interaction is still going to be critical to their success. If traditional grocers fail to adopt automation technology, Amazon will make them extinct. A review of the general merchandise sector over the past decades proves that.

Labor Shortages

The COVID economy has created a huge chasm between the haves and the have nots. But as the pandemic winds down, it is clear there are more jobs than workers in many sectors.

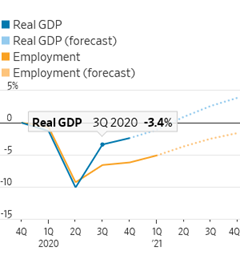

Economists surveyed by The Wall Street Journal project U.S. gross domestic product—the value of all goods and services produced—will grow 6.4% this year, measured from the fourth quarter of last year to the same period of this year. That would lift output to nearly 4% above its pre-pandemic level measured in the fourth quarter of 2019 (see fig. 2). Meanwhile, economists expect employers to add 7.1 million jobs in the 12 months ending in December 2021, a gain of 5%. |

The economy grew at a 4.1% rate in the fourth quarter of 2020, and employment demand is on the rise. Many of the positions that automation replaces are the most challenging to fill and have high turnover. The costs of constantly recruiting training and then losing employees is a heavy burden on retailers. While the average employee turnover for all U.S. industries is around 19 percent, the rate in the retail industry is just above 60 percent, according to the National Retail Federation.

Looking past the current economic cycle and pending labor shortages, there is an even more pressing macro trend. There has long been a concern that human population growth would outstrip the capacity of the planet, but we now face population decline.

|

Automation presents an opportunity to increase the productivity of each worker and raise the standard of living while offsetting current and impending labor shortages.

Quality of Work and Career Development

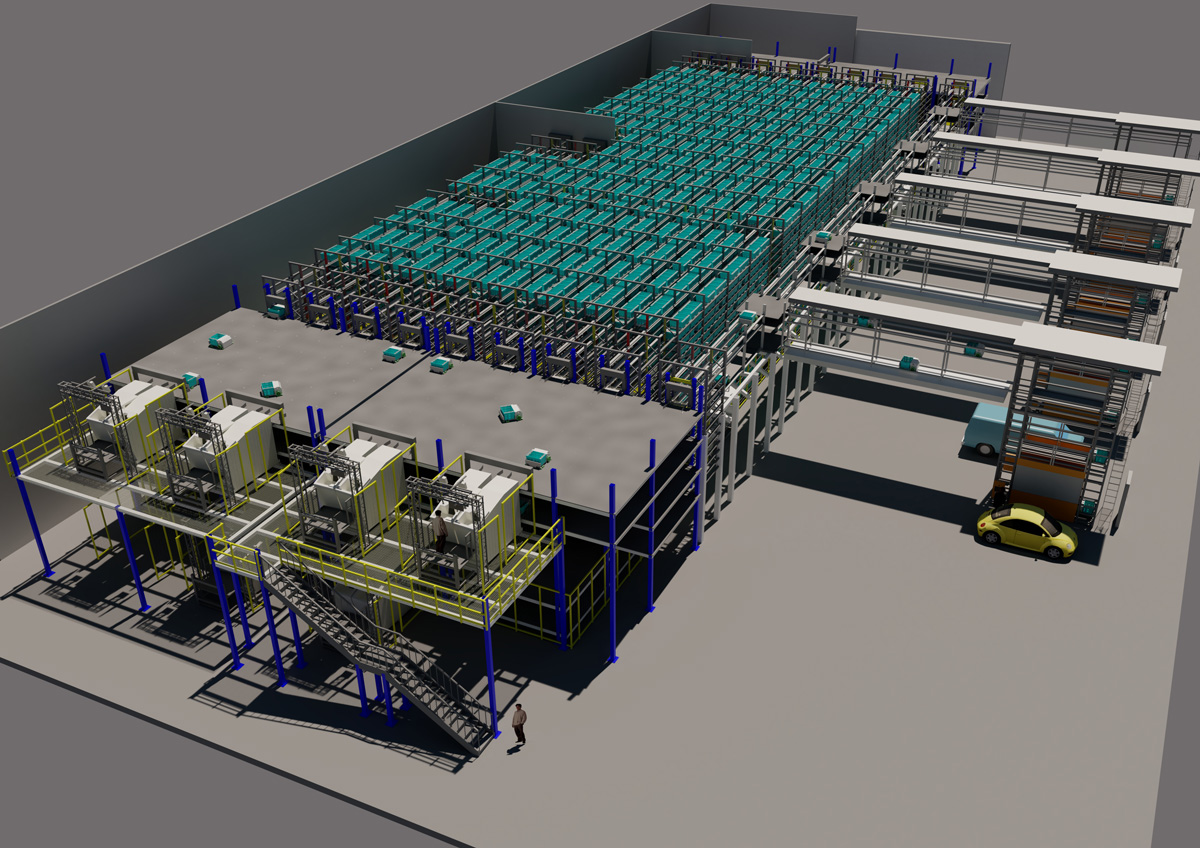

Alert’s mission statement starts out, ‘Our mission is to improve lives through innovation….’ Alert automates e-grocery fulfillment and other e-commerce verticals by designing robotic systems to perform tasks normally performed by humans. For grocery customers, it’s simple to see that we are improving lives by reducing the cost of e-grocery fulfillment and getting those orders to you faster and more accurately.

When meetings end early, the meeting organizer often says, ‘I’m giving you time back.’ Automating the grocery shopping experience does just that at scale. The average shopper in the U.S. spends 53 hours a year buying groceries, not including transportation time. And about 30% of the population are active grocery shoppers according to FMI data. So, if everyone shifted to e-grocery shopping in the U.S., we would be giving back 5.25 BILLION HOURS per year. Over the course of a lifetime, each person would get back 3,100 hours which is almost two years of work, play, family time or education!

But would a retail grocery worker agree that automation in the form of Alphabot is improving their lives?

There’s no question that I have achieved a privileged position in the workforce, but I have also landscaped, washed dishes, and maintained heavy equipment. I know both the rewards and the demands of physical work; it can wear you out. I was recently chatting with a worker, a retail grocery veteran who is using the Alphabot platform and asked what she thought of the system, she responded, ‘this is the best job I have had in my 14 years!’

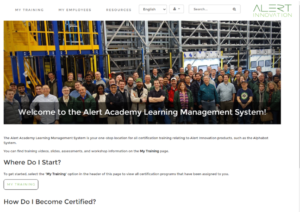

Staffers working with robotic systems are affectionately called bot wranglers. The implication is that the robots are working for you, not the other way around. This is Alert’s goal. Robots increase productivity, eliminate repetitive tasks, and make work better. Retailing often has the perception of a dead-end job. While it is true that retail tends to be an entry level job into the workforce, most retailers provide education, training, and career development. Alert developed the Alert Innovation Academy to train existing retail employees to work with the Alphabot system. Alert Innovation Academy has a career development trajectory that graduates workers from operators to robotics tech 1, tech 2 and even systems operation manager. Associates can start stocking shelves and become a robotics expert!

Alert developed the Alert Innovation Academy to train existing retail employees to work with the Alphabot system. Alert Innovation Academy has a career development trajectory that graduates workers from operators to robotics tech 1, tech 2 and even systems operation manager. Associates can start stocking shelves and become a robotics expert!

Beyond the retail grocery worker, third party technical support and service companies are also trained via the Alert Innovation Academy to expertly maintain the Alphabot platform. This is just one part of a whole new ecosystem that automation drives – manufacturing, engineering, quality, service and more. Alert strives to turbocharge this ecosystem and corresponding job growth in the U.S.

And what happens to the grocery experience?

The immediate impact of automation improves the shopper experience on many levels – aisle congestion from gig shoppers goes away, order accuracy goes up and deliveries are faster. Looking further down the road, there is a tremendous opportunity for grocers to redeploy employees in the store so they can focus on experiential shopping. This is a concept at Alert called Novastore. Human interaction with the butcher, the baker, the team in produce, in store cafes and cooking demos. It is back to meeting basic human needs of shoppers and real workers engaging in real interactions in person.

So, are robots good?

If you are familiar with Peter Diamandis’ book ‘Abundance’ or are a student of psychology, you will appreciate that we humans tend to look at things with a half glass empty perspective. The fear of potential loss is much greater than our appreciation of potential gain.

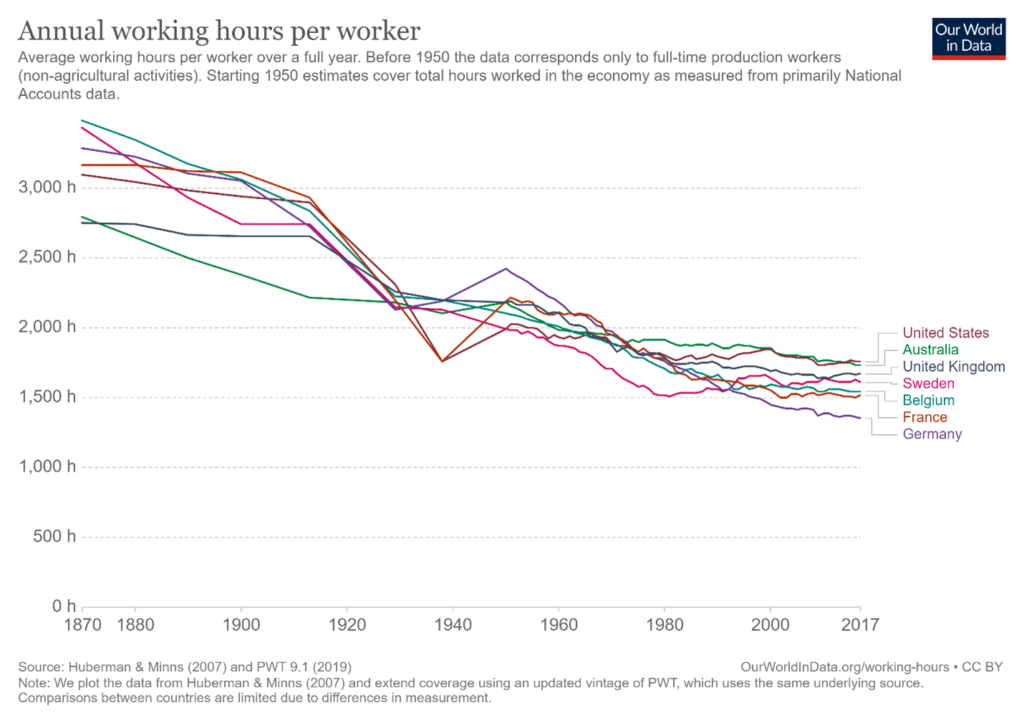

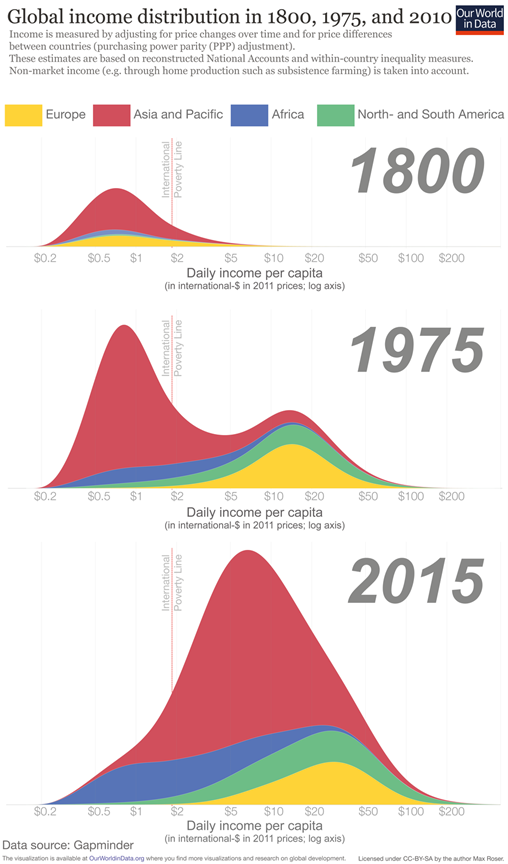

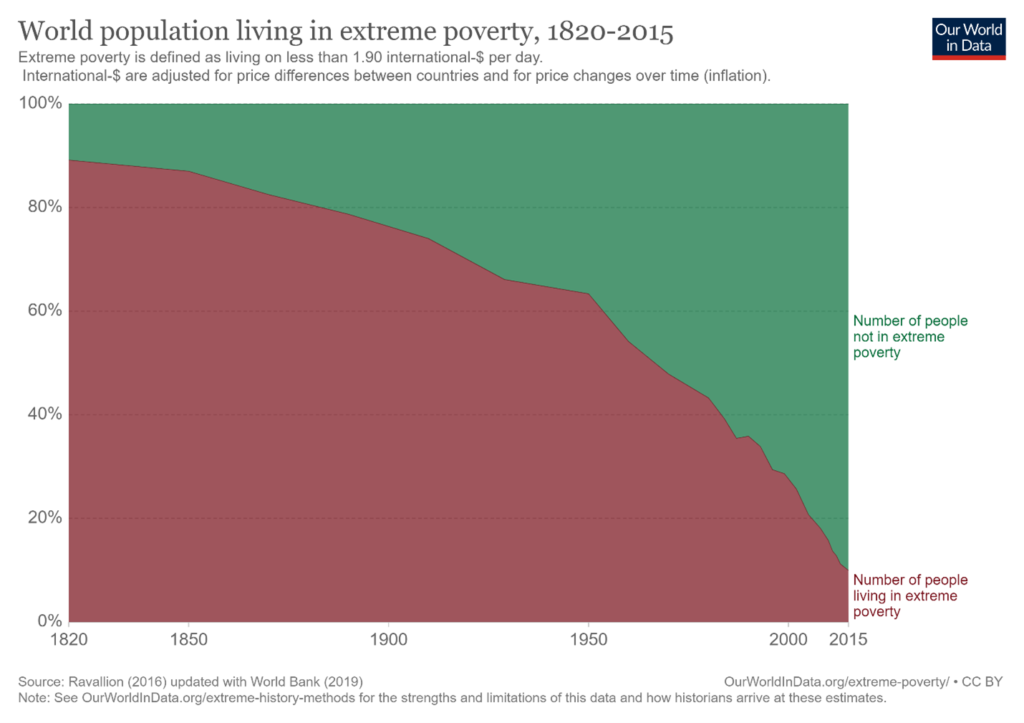

However, historical data tells us that things keep getting better. If you look at the following charts, we are working almost half the hours today as in 1870 and wages have increased over 20 fold and poverty is down 80%.

So are robots good? They are the continued progression of electricity replacing candlelight, and cars replacing horses. They deliver more productivity, higher quality work and an increased standard of living, giving us back time to engage with customers and get back to basics of building a better future together with few downsides.